Wrocław University of Environmental and Life Sciences

Norwida 25 st., 50-375 Wrocław

Wydział Biotechnologii i Nauk o Żywności

Wydział Przyrodniczo-Technologiczny

NewDryTech AS

New & Improved Drying Technologies

Elvevegen 25, Trondheim, Norway

CEO Odilio Alves-Filho, Director of Research

NewDryTech AS provides consultation and design of ecologically and environmentally friendly drying technologies while prioritizing sustainability and processes conducting to better current and future society. NewDryTech AS strategies focus on drying based as contributor to a circular economy including converting and recycling wastes and wet organic byproducts to valuable dried powders. The focus is on energy recovery and efficiency by applying advanced green heat pump systems and uniquely developed heat-mass exchangers for moisture and energy recovery. Additionally, the dryers and components designed by NewDryTech operate with capacity and performance that provide revenue and profit.

EnerDry ApSKongevejen 157, Dk-2830 Virum, Denmark

phone: + 45 45 260 440

e-mail: Info@EnerDry.dk

www.enerdry.dk

EnerDry ApS is a Danish company supplying large scale dryers and equipment and consultancy for industries with challenges of drying bulk particulate materials such as beet pulp of sugar factories. Large dryers evaporating up to 70 tons of water per hour requires huge energy supply and causes a severe atmospheric pollution if drying is done with air in open cycle. Traditionally drying in the sugar industry is done in rotating drum dryers with such downsides as pollution and large energy consumption. This was the background for development of a new technology where pulp drying occurs in a fluidized bed under pressure driven by superheated steam. The drying of beet pulp in superheated steam under pressure is integrated to the steam system of a sugar factory. The superheated steam drying takes place in a closed vessel implying no air pollution. The drying does not consume energy and all supplied energy is reused. One large dryer of 70 tons water removal per hour provides a saving of 200 tons of coal per day and gives the same daily reduction of CO2 emission as a windmill park with sixty windmills, each with a 2 MW capacity. Subsequent to extensive tests 22 industrial dryers built, each with capacity up to 70 tons water evaporation per hour. Currently, industrial dryers are being built in Japan, Denmark and Serbia. Besides beet pulp, this technology is applied for drying of bio fuels like wood chips, bark, and waste water sludge. The development is still going on for adapting the dryer to new products.

PromisTech sp. z o.o.Danuty Siedzikówny 14 st., 51-214 Wrocław

phone: +48 71 344 70 78

e-mail: biuro@promistech.pl

www.promistech.pl

Promis-Tech sp. z o.o. designs equipment and devices that incorporate novel technologies based on microwave energy. By bringing science and industry together, the company offers unique technical solutions, both in a laboratory and industrial scale. We find inspiration in combining non-standard technologies, which allows creating innovative prototypes adjusted to, among others, food-processing, or manufacturing top-quality products that meet the expectations of our Clients.

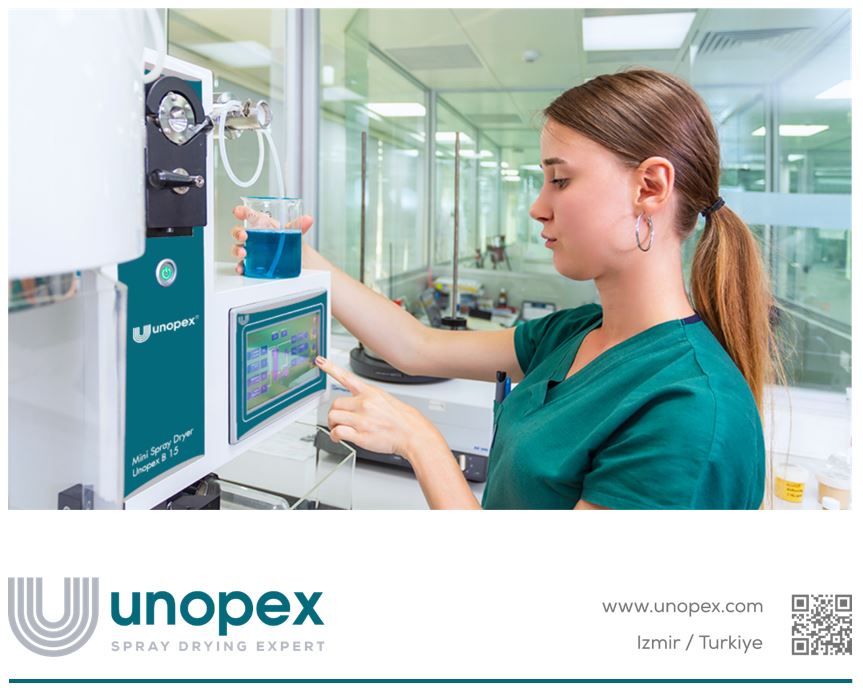

Unopex1429 Sk. No:9 Bornova, Izmir, Turkey

phone: +90 232 479 80 17

e-mail: unopex@unopex.com

www.unopex.com

Unopex focuses on to design and manufacture of spray drying, solid-liquid extraction and evaporation technologies.

We strive for researchers and manufacturers to make real their projects serving humanity in a safer and greener world.

We serve endless human potential and richness of life with our experience, professionalism, motivation and talent.

Many universities, institutions and R&D centers active in the fields of food, pharmaceutical, nutraceutical, chemical and cosmetics.

File to download:

Ads Unopex 2022.pdf

Bempressa

Zakład Produkcyjny Bempresa Sp z o. o. w Lublinie

Anny Walentynowicz 34 st., 20-328 Lublin

phone: +48 81 44 10 293

e-mail: contact@bempresa.com

Zakład Produkcyjny Bempresa specializes in the production of milk powders, including products such as skimmed milk, sweet whey, whey protein concentrates as well as high-quality milk substitutes made solely on the basis of milk or mixtures of milk with vegetable oils. Moreover, modern technological lines allow the processing of liquid colostrum, on the basis of which the company is able to produce skimmed colostrum powder and clarified butter with colostrum. Due to the vast experience and modern technological facilities, the company is able to adapt to market requirements and create new and unique, tailor-made products such as the production of food with the halal and kosher status, which have been confirmed by the most recognized certification bodies in the world. Additionally, the company meets the most rigorous food safety standards, which is reflected in obtaining the BRC v.8 certificate.

DONSERVMichała Spisaka 31 st., 02-495 Poland

phone.: +48 22 863 19 30, +48 22 863 19 33

e-mail: info@donserv.pl

www.donserv.pl

DONSERV was founded in 1989. We are a company with private Polish capital. We operate on the basis of direct contracts with manufacturers of laboratory equipment. We carry out assembly and training in the use of purchased equipment. We provide warranty and post-warranty service. Our sales representatives and service engineers regularly train at the manufacturers of the offered equipment.

- Warsaw Headquarters

- Branch in Olsztyn (North - Eastern Poland)

- Branch in Poznań and Wrocław (Western Poland)

- Branch in Katowice (Southern Poland)

- Branch in Kielce (Poland South – East)

GP Klasa

Grupa Producentów KLASA Sp. z o.o.

Klementowice 136, 24-170 Kurów, woj. lubelskie

phone: +48 81 88 23 280

e-mail: gpklasa@gpklasa.pl

The GP Klasa company GP KLASA Sp. z o.o. founded in 2008 is a fruit processing plant located in Klementowice near Kurów in Lublin province in eastern Poland. Extensive development and the increasing number of offered products make the company open to new export directions and contacts. The Frigo Klasa Company established in 2013 as a part of the Klasa Group produces over 100 tons of freeze-dried products per year, and keeps expanding the machinery stock. Thanks to next development projects, the company will launch new freeze-drying machines next year.

HARTIMEX Sp. z o.o.Automatyka przemysłowa

Sławacinek Nowy 28F, 21-500 Biała Podlaska

phone: +48 83 343 00 00

e-mail: biuro@hartimex.pl

www.hartimex.pl

Hartimex Ltd. started operating in 1996. From the beginning, the company has been focused on the implementation of projects related to the automation of technological processes on an industrial scale. The company is characterized by many years of experience and unique competences, mainly in the sanitary, food and tire industries. The company owes the reliability and quality of its projects to the use of devices from leading manufacturers of control and measurement equipment and industrial automation. Thanks to cooperation with reputable design offices and significant contractors of investment tasks, the company's portfolio includes innovative and at the same time reliably implemented projects.

"PASZKÓW" Farma Tadeusz Kaczmarczyk

Rzemieślnicza 1 st., 58-100 Świdnica

phone: +48 507 017 269

e-mail: biuro@paszkow.com

The "PASZKÓW" Farma Tadeusz Kaczmarczyk company, established in 2004, conducts research and development activities in the field of processing plant materials with the use of extraction, distillation and drying techniques. The offer of the company cooperating with the Wroclaw University of Environmental and Life Sciences includes technologies and devices for the production of black garlic as well as plant products and preparations with a pro-health effect.

Sante sp. z o.o.

Jagiellońska 55a st., 03-301 Warsaw

phone: +48 22 811 50 37

e-mail: sante@sante.pl

Sante sp. z o.o. is a Polish company that was established in 1992 as a family business, setting trends on the healthy food market from the very beginning. The company's mission is to take special care to provide consumers with food that has the most beneficial effect on health. The rich and diverse offer of Sante includes about 200 products in the following categories: breakfast cereals, cookies and cereal bars, groats, grains, protein bars, peanut butters, vegetable drinks, vegetable pastes and pates, professional sports nutrition and others. Sante's showcase is the constantly expanding family of products without artificial additives.

Zakład Zielarski „KAWON - HURT” Nowak sp.j.

Krajewice 119 St., 63-800 Gostyń

phone/fax: +48 65 572 08 22, +48 65 572 34 60

e-mail: kawon@kawon.com.pl

Kawon is a Polish family company with over 50 years of herbal tradition and since 1990 a company producing medicinal herbal preparations, fruit and classic teas and spice herbs. The past years have been marked by constant expansion of the production and warehouse base, improvement of production technology, Thanks to the systematic expansion of the commercial offer, the company have become the leading manufacturer of medicinal herbal teas in Poland. The company's goal is to manufacture products of the highest, repeatable quality, safe for health and meeting the needs and expectations of customers.

Polish Academy of SciencesPałac Kultury i Nauki, Plac Defilad 1, 00-901 Warsaw, Poland

www.pan.pl